OUR PRODUCTS

CONtinuous space dye

A continuous system that prints dye in patterns, fixates the dye, dries the yarn and winds the yarn back onto a package completely ready for the next process.

For full details and capabilities of the MDS III Continuous Space dye, please watch our video!

About the process

- Nylon Fixation/HeatSet

- Polyester Fixation/HeatSet

- Acrylic Fixation

- Wool and Synthetic Blend Fixation/HeatSet

- Superior Washing

- Superior Drying

- Superior Shade Match

- Superior Pattern Software and Controls

- Minimal dye waste

- Micro Space to Ultra Long Space and including solid shade capability.

Rototwist

Using High Speed Servo Technology, the Roto-Twist is a break-through in the preparation of plied yarn. The Roto-Twist imparts alternating S and Z twists separated by a carefully positioned air-tack. The precise placement of this air-entanglement tack-point gives each twist unequalled uniformity. With the ability to place these transition points as much as 2.4 meters apart, the Roto-twist unit can also be installed in line with your heatsetting equipment, creating a single process that can greatly reduce your processing costs.

About the process

- Nylon Fixation/HeatSet

- Produces 2, 3, 4, 5 or 6-ply yarns in one pass.

- Designed for continuous operation at 600 meters per minute.

- Greater texture, color clarity and styling potential at a fraction of the cost

- Easily monitored and controlled via a touch screen.

- Yarn accumulator allows for continuous operation during the doffing process, and for product inspection prior to winding

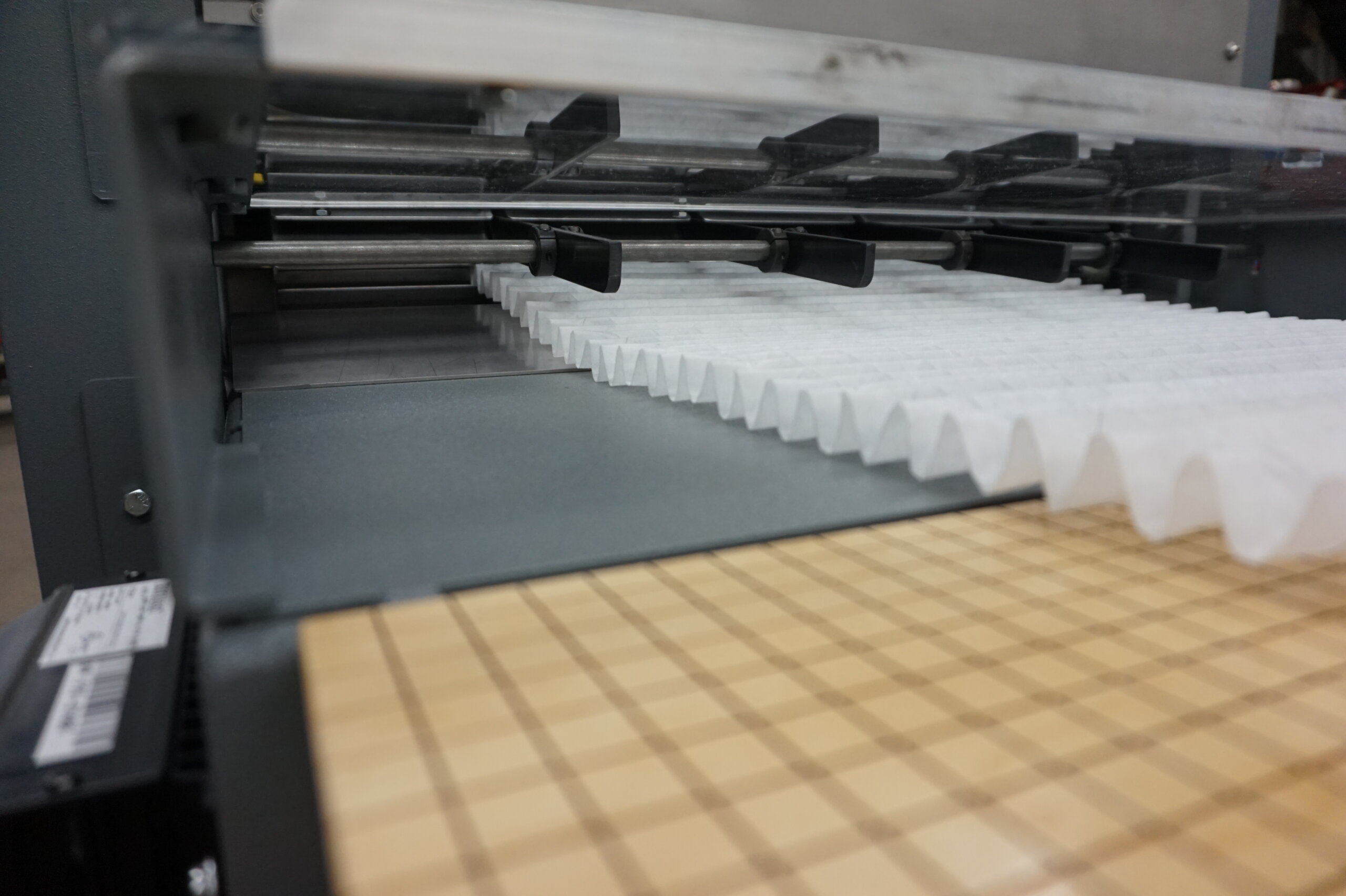

HEAT SET

After evaluation of the industry standards in heat Setting, The BCA Product line offers many features that improve both the quality and reliability of the Continuous Autoclave system. Starting with our Patented newly design sealing heads, a low maintenance belt drive system and a hydraulic free sealing system begin the process of the Belmont Continuous Autoclave. Our Patented tunnel design, Cooling chambers, and control system allow for the best quality heat setting in the industry. Please refer to the video below for technical data and understanding of our BCA product line.

** Please note ** At this time, the Newly designed sealing heads are not explained in the Video. Please contact us for further information regarding this product!

About the process

- Up to 72 running end configuration

- Superior sealing head temperature control

- Patented design eliminates “burn marks” during belt stop.

- Superior heat set temperature and pressure control.

- Engineered for Low maintenance and minimal parts usage.

AIR ENTAnGLEMENT

Our process allows constant applied air pressures ranging from 40psi-125psi to blend up to 6 ends of yarn into the final product. Belmont’s process is why we are chosen for high quality products that need end to end consistency to avoid striations in the final product.

About the process

- 6 or 8 spindle arrangements available

- Entangle up to 6 ends per spindle with standard V-shape creel

- Produces air entangled yarns from 500 to 30,000 denier

- Winding speeds up to 850 ypm

- Automatically doffs packages

- Yarn measurement counter within +/- 2%

- Compact and energy efficient design

- Can be fitted with Belmont RotoJet air entanglement system

CUSTOM MACHINERY

Belmont has a long history of creating new products and developing custom solutions to meet the specific needs of manufacturers in various industries worldwide. Belmont’s sales and engineering teams works closely with a wide variety of customers to design, manufacture, install and support custom equipment.

About the process

- Mechanical / Electrical Engineering

- Design / Develop to meet specific criteria

- Manufacturing and assembly of the machinery

- Installation

- Technical Support

SERVICES

OEM Technician and Equipment relocation

Belmont Textile Machinery considers service as a priority. Our staff is equipped with Safety education, professionalism, customer communication, and the equipment to service and troubleshoot our manufactured machinery as well as specializing in machinery relocations. Please contact us for Service pricing.

Come check us out!

Monday – Thursday

8:00 AM – 5:00 PM EST

Friday

8:00 AM – 4:30 PM EST

Contact

Phone

+1 (704)-827-5836

info@btmc.com

Address

1212 Catawba Ave.

Mt. Holly, NC 28120, US