WE BELIEVE IN A PRODUCT THAT LOOKS INCREDIBLE

Belmont Textile Machinery Company pays attention to detail and the importance of process/production quality needed by our customers.

Continuous Space Dye

A continuous system that prints dye in patterns, fixates the dye, dries the yarn and winds the yarn back onto a package completely ready for the next process.

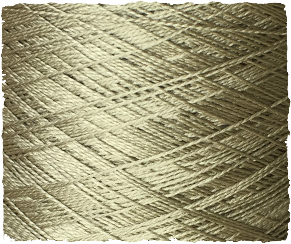

Air Entanglement

Using airjet technology, Rotojet, and tack removal system, our processes allow for many looks to combine multiple yarns for the highest quality in the industry.

RotoTwist

Using High Speed Servo Technology, the Roto-Twist is a break-through in the preparation of plied yarn by imparting alternating S and Z twists.

HEAT SET

Our patented Continuous Autoclave technologies have proven to be of highest quality within the industry, especially dyeable goods.

Our Story

Belmont Textile Machinery Company has been designing, engineering, supporting, and inventing products for the Textile industry since 1955. Our company started by designing robust equipment suitable for large count staple products specifically in the carpet industry. Our mission is improving your quality, increasing your production and reducing your maintenance and repair costs by using our equipment. In the 1960s, our company invented our first machine, the 6810 Take up winder. This changed the carpet yarn industry forever. As we continue to invent machinery and automation, we have invented state of the art continuous space dyeing processes, 5 generations of automatic take up winders, continuous air processes, and Continuous Heat Set applications. As a company over the years, we have built up a great experience and knowledge in many areas of textiles through Research and development, NDA projects and our great relationships with our customer base. Belmont Textile Machinery Company is a 3rd generation Family business. WE plan to continue our tradition and support going forward!

Come check us out!

Monday – Thursday

8:00 AM – 5:00 PM EST

Friday

8:00 AM – 4:30 PM EST

Contact

Phone

+1 (704)-827-5836

info@btmc.com

Address

1212 Catawba Ave.

Mt. Holly, NC 28120, US